Koboldt Consulting S. El Monte, CA – Lean Business Consultant 10/2023 – 03/2024

Client: Quintus

My role: Lean Business Consultant, hired 2nd time by CEO to implement lean manufacturing

Manufacturing: Luxury high-end furniture built in East Los Angeles

Staff size: 35

Products: tables, chairs, sofas, cabinets, beds, shelves

Wood: oak, mahogany, walnut, and exotics; quarter sliced, plain cut, rift cut veneers

Metals: bronze, brass, copper, aluminum; polished, brushed, antique finishes

Paint: 35+ different styles of finishes, low VOC (California)

Actions:

𝗖𝗛𝗔𝗟𝗟𝗘𝗡𝗚𝗘 #𝟭: Lack of standardization around production planning with ship-promise compliance <20% and 27-week lead times (16 week industry average) after challenge of explosive sales growth, ramping up frame-shop in-house, and large-scale custom projects.

CHALLENGE #2: Reporting was segregated and had bad data. Late orders were growing exponentially. Extremely upset customers!

𝗖𝗛𝗔𝗟𝗟𝗘𝗡𝗚𝗘 #3: Culture was weak and mis-aligned. Unhappy employees. Numerous operational mistakes being made. Poor communication from one person to the next. No alignment towards common goals/KPIs.

Results:

➤ Lead times reduced below industry average of 16 weeks currently.

➤ Ship promise compliance boosted 17%.

➤ Organized capacity-based planning system maximizing efficiency.

Acuity Brands Los Angeles, CA (remote) – Director, Architectural Technical Sales 02/2017 – 08/2023

Reported to V.P. of Architectural Services / SVP of Architectural Lighting Solutions.

Led Architectural Technical Sales (ATS) team of 19 ATS Managers with seven direct reports, covering 3 regions across 23 states, Western Canada, International (Latin America, Europe, Asia, Middle East), and enterprise accounts.

SALES

Achieved sales revenue growth of 13% FY22, 7% FY21, 7% FY20, 12% FY19, 17% FY18, 12% FY17, growing one architectural brand $100M+ in five years.

CUSTOMER EXPERIENCE/SERVICE

Relentlessly focused on reinventing the service model for our agents/contractors/specifiers/clients, creating a unique tailored customer experience, resulting in lighting industry best service:

- 9.8/10 CSAT score for our teams service levels, increased from 8.1 in FY19.

- Reduction of tech support cycle time from 6.3 to 1.3 days.

- Reduction of submittal cycle times from 5.2 to 1.8 days.

- Trimmed modification turnaround from 7.1 to 1.2 days.

OTHER

Earned SPOT award for Light the Way Leadership AIP; resulting in an overhaul of leadership competencies and assessments for entire company by 2023.

Served on Women’s Network (ERG) in FY22 and FY23; led book club, leadership speaker series, and self-defense classes.

LEAN

Instituted 37 lean process improvements and authored seventy-one standard work instructions. Tools: A3, value stream mapping, 5 Why, Fishbone, DMAIC, Paynter charts, Standard Work, SIPOC, Pareto charts, Gantt charts, Value Stream Mapping, FMEA, 5S/6S, and House of Quality.

Kaizens: $3.2M in lean savings!

2/20/17 – Implement SSQ process to improve sales samples to museum quality

3/20/17 – Value stream mapping of architectural services w/ lean consultant

5/3/17 – Palletization in linear runs / kanban production facility

6/29/17 – Reducing engineering cycle time by 44%

9/11/17 – Quality transformation at production facility, reducing quality claims by 80%

9/25/17 – Value stream mapping customer care / architectural technical sales; reduce response times

12/5/17 – Reducing escalations Brand X; 72% improvement

2/8/18 – Reducing escalations Brand Y; 71% improvement

4/15/18 – Reducing escalations Brand Z: 65% improvement

11/29/18 – Define event for commitment orders

12/11/18 – Sales sample kaizen

2019

➤ Championed an Annual Improvement Plan (AIP) with senior leadership sponsorship aimed at reducing the lead time and improving quality of our no-charge sales sample order process.

* Implemented robotic processing with 3rd party vendor.

* Wrote 5 new standards of work.

* Result: 10,000%+ decrease in lead time

➤ Developed a digital order tracker and notification system utilizing agile ‘sprint’ methodology; one of eight employees selected by CEO to contribute to Better.Smarter.Faster – Where’s my stuff project, delivering solution within six weeks. This created the foundation and framework for the BSF operating model.

➤ Culture annual improvement plan (AIP) focused on leadership “Light the Way”. Earned SPOT award.

➤ Championed FLAP initiative leading seven teams as part of a $200M corporate growth initiative, delivering $11.72M vs. $10M goal. The focus was on taking share from one of our top competitors by using House of Quality, a quality functional deployment tool for competitive and technical benchmarking. Delivered monthly report out to executive team.

➤ Coached new operations leader for two months on $35M annual improvement plan, building off the momentum of the FLAP initiative. This leader was promoted to VP of CX.

*All true data hidden to protect privacy of company.

Stock: AYI – $4B in 2022, $3.5B in 2021, $3.2 billion in 2020, $3.8B in 2019.

Acuity Brands Chatsworth, CA – Solutions Project Manager 07/2016 –01/2017

Acuity Brands is a $3.7 Billion provider of lighting and energy management solutions (IoT, smart city, led).

Promoted 2x from this role after 6 months to architectural team.

Led multi-phased, $multi-million projects, cradle to grave.

Managed 25+ projects for 3 agencies from Ventura to San Diego to Vegas, as well as supported 7 sales reps from Western Canada to Colorado to Phoenix.

Applied lean methodology to institute and organize 30 standards of work for the project management team of 20.

Navigated a complex matrix organization to:

– pull hundreds of orders through the supply chain

– minimize post sales delays

– improve engineering cycle time

– reduce coding cycle time

– get answers to complex tech or product support questions

– assist sales team

Participated in tech support kaizen, resulting in a reduction of escalations by 13%.

Reported to Director of Design & Application Services, reporting to V.P. Customer Experience.

Geoff Koboldt is one of the most upbeat and energetic people and manager you can possibly have. He is always spinning problems as opportunities and providing you with a chance to improve on yourself and career. He provides clear instructions of what he expects and tools for you to achieve your goals. He is available and open to communicate and hear and share ideas. He is a pleasure to work with and for. He has this stunning and insatiable habit for learning and practicing what he learns and generously sharing it.

I am fortunate to work for Geoff, a manager who is focused not only on growing the company’s bottom line, but also on his employees’ professional growth. Geoff understands that leadership is more than just delegating tasks. He takes a genuine interest in what drives you both personally and professionally and gives you the tools necessary to make you more successful. I consider myself very lucky to work for a manager like Geoff.

Koboldt Consulting Santa Monica, CA – Project Consultant (short-term contract) 08/2015 – 06/2016

Client: Somadome, Inc.

Contracted by CEO to manage multiple projects including systems integration, supply chain and logistics for this luxury company introducing a high-tech meditation pod to the health and wellness industry globally.

- Developed overarching global strategy and infrastructure with CEO and IT architect including user experience, product life cycle phase analysis, market penetration, and systems integration.

- Instituted lean systems and processes for managing the supply chain with manufacturing in Southern California; negotiating contracts with vendors; ensuring just-in-time delivery; assurance of inventory control.

- Collaborated with engineering and product development to build a robust, high-quality product, troubleshooting and training manuals and videos, and a quality control system.

- Created a dashboard and database that integrates all systems and departments seamlessly.

- Streamlined communication via Confluence + Dropbox + Trello + Slack.

Quintus Home West Hollywood, CA – Lean Business Consultant 03/2015 – 09/2015

Contracted by CEO to implement lean systems and operations for his new luxury furniture company.

- Implemented lean processes including development of 20+ new standards of work; 6S, value steam mapping, DMAIC.

- Developed a 5-part metric system and continuous improvement board with 60+ actionable items.

- Instituted a detailed management performance system for employee development improving efficiency by 33%.

- Created a production schedule board for vendor management resulting in improvement of on-time performance from 20% to 65%, while increasing first-time quality by over 14%.

- Led IT project setting up new systems with All Orders, QuickBooks, and Salesforce.

Rose Tarlow Melrose House, Inc. West Hollywood, CA – Director of Operations 01/2014 – 02/2015 In charge of all operations for this luxury, high-end company serving the interior design community. Products include furniture, textiles, lighting, rugs and accessories. Led management staff of 16 including Production, Purchasing, Customer Experience, Warehouse, Quality, Logistics, and Special Projects. Results: reduced lead times from 20.9 weeks to 16.4 weeks.

- Improved on-time performance from 40% to 78%, while simultaneously reducing the lead-time from 20.9 to 16.4 weeks.

- Drove new levels of first-time quality after overhauling the entire quality process contributing to an 18% improvement.

- Utilized lean tools to drive continuous improvements resulting in 45 new standards of work written, identifying top 3 customer needs, eliminating low selling skus, reduced shipping errors by 10%, and increased customer satisfaction by 50%.

- Transformed the culture positively with management performance system, 360 reviews and CXPA training. Member of Customer Experience Professional Association.

- Launched 35 new products, partnered with Cox London to release 60 new products, launching new finished sample program.

- Managed the relationship with 25 local vendors producing 150+ sales orders per month, 1000+ skus, while working with 200+ designers, design firms, and 17 partner showrooms, as well as our flagship store in LA.

- Navigated 3 highly-customized projects in the $2-5M range for high-profile billionaire clients.

Geoff is one of the strongest operations leaders I have had the pleasure of working with. He was brand new to our industry when he joined Rose Tarlow Melrose House. He developed an understanding of the business very quickly. He listened and absorbed; never jumping in with suggestions or plans until he had a full understanding of the situation. He was meticulous at putting in place systems and metrics, and also developed a high level of accountability and ownership with his team. He was an amazing leader. He stepped into a very difficult situation with legacy employees who didn’t want to change and basically no systems in place. He lead by example; pulling the team along first, and pushing only when he had too. He then created his own systems using any resources he could pull together. And the results spoke for themselves. We saw massive improvements in on-time %, first time quality and customer satisfaction. I recommend Geoff highly. Any organization will be lucky to have him leading their team.

Geoff is a strong lean operations leader with a focus on continuous improvement. I have seen his key skills revolve around optimizing process and documentation. He also has experience with management performance evaluation systems and is adept at implementing the framework. Geoff would be a valuable member of teams looking for these key skills.

I had great success working with Geoff at Rose Tarlow Melrose House. Geoff’s fostering innovation helped me develop better, faster ways to do things. He takes the lead in setting new business directions, procedures and policies. Under his management, he helps me develop a clear understanding of what I will need to do differently as s result of changes in the organization. I admire his confidence to allow me the freedom to decide how I will accomplish our goals and resolve issues. I highly recommended Geoff for his leadership and his ability to empower employees.

You don’t ever forget leaders like Geoff Koboldt. Geoff is the poster child of delivering value and quality to customers. His ability to inspire others to get down to the roots of problems and fix them is exceptional and beyond expectations. His unique management performance system identifies where each employee’s strengths and weaknesses are so every employee knows exactly where to focus their energy as he quickly guides them from goodness to greatness. There is no doubt that he cares for each employee as if they were his own family. His level of emotional intelligence (EQ) is unmatched and when combined with his business intellect, it’s a knockout combination. I highly recommend Geoff to the nth degree.

BambooBuddy, LLC. Oceanside, CA – COO 5/2008 – 01/2014 In charge of all operations for marketing and distributing products made from bamboo under various brands to Lowes Home Improvement Store and Home Depot, with pending Walmart deal for consumer products. Products include fencing, skateboards, dishware, sunglasses, and natural deodorizers. Directed $750K budget and a direct staff of 19 including Operations, Sales, and Warehouse Managers, as well as 5 independent sales representatives in the U.S. Results: built business from startup to multi-$million.

- Developed quality assurance program at factory and distribution level with less than .5% customer defect rate.

- Deployed Kaizen projects using Lean and Six Sigma techniques; cut warehouse labor expense by 7%, increased fill rate from 94.55 to 99.87, and raised employee productivity by 23%.

- Increased sales 51% year-over-year by educating Lowes management in merchandising techniques.

- Expanded distribution through Lowes from 40 stores in 3 states to more than 450 stores in 30 states.

- Reached 99% on-time shipping and delivery gaining A-level rank from Lowes for inventory turns, quantity fill rates, quality returns and monthly sales as a vendor.

- Achieved 14% reduction in operating costs enabling investment in other brand pursuits without additional financing or loss of equity. Instituted process improvements resulting in consecutive annual 12% budget reduction.

- Cut and right-sized inventory, reducing by $102K and developed accurate JIT forecasting model.

Geoff is an amazing asset to our corporation, he is also a great friend. I could NOT hope for a better business partner and co-owner in our company. His work ethic is second to none, his creativity is inspiring and his attention to detail impeccable. I highly recommend Geoff! P.S. Don’t let him catch you slacking.

Geoff is a very astute individual with the company in mind. He is a very motivated individual who is capable of not only promoting direction in leadership but also ready to dive into any role when needed to assist. I recommend Geoff not only because of his strong work ethic but his attention to his peers.

Geoff constantly challenged his employees to produce their best work. As an innovative and inspirational leader, he motivated me to turn in only the highest quality work. Another great skill I learned from Geoff is time management. Geoff excels in this area and he would drive my efficiency week to week so that I would manage my time more effectively. Ultimately, his dedication to the success of the company and his employees are second to none.

As an accounting assistant at Bamboo Skateboards, I gained many meaningful insights into both the accounting profession and the business world thanks to the strong leadership of President Geoff Koboldt. As an international graduate-degree intern from China, I learned to organize my work properly, multi-task and manage my time efficiently, which enabled me to adapt to the American working environment quickly. This greatly prepared me for a smooth transition into an accounting career at Deloitte. I am confident Bamboo Skateboards has a promising future under the guidance of such a talented and hard working leader such as Geoff.

Dark Horse Distribution, Inc., Marina Del Rey, CA – VP of Strategic Operations 9/2006 – 3/2008 Charged with turning around this struggling $4M+ action sports company that was operating at a loss. Directed production, finance, accounting, and strategy for this company with 13 employees. Managed $1.6M operating budget. Results: executed new business plan, reduced operating costs by $753K, established budget and financial accountability.

- Developed quality control process holding defects to less than .01% while increasing productivity by +15%.

- Reduced COGS by $740K and sourced new overseas factories for key products; negotiated with American vendors to reduce costs; savings freed up cash to pay off outstanding payables and invest into marketing and fresh branding efforts, including individual product updated logos, brand identity and new apparel line.

- Expanded Internet sales by more than 5,100%; orchestrated design and launch of 2 new Websites, including SEO, Adwords, and shopping cart with OS commerce.

- Reduced inventory costs by $50K and increased warehouse and office efficiency by applying 5S and lean techniques.

- Established new sales quotas, commission structures, and sales training.

Milgard Manufacturing, Inc., owned by Masco Corp, Simi Valley, CA – Materials Manager 5/2005 – 8/2006 Directed purchasing of more than $45M inventory for this $120M window and door manufacturer with 400+ employees. Reported to Finance Manager and directed 32 staff and $1.1M budget. Instituted all lean practices for company. Results: saved total of $1.4M through reduction in GAP within 1 year, utilizing lean six sigma tools.

- Recognized as #5 plant out of 18 for GAP, a rise from 11th place. Earned #1 materials management team.

- Increased productivity on aluminum line from .72 units/hour to .90.

- Gained $110K additional revenue by negotiating waste removal plan for broken glass and scrap aluminum.

- Reduced physical inventory write-offs by $203K; applied 5S to each production line and trained staff.

- Improved cycle count accuracy from 83% to 97.3%.

I worked with Geoffrey Koboldt at Milgard Windows & Doors on many projects around operations and inventory controls. He is able to understand how his teams affect customer service and the bottom line to the company and how to manage those teams to provide a very high level of both. Geoffrey was able to grasp complex concepts very quickly and was always bringing new ideas and out of box thinking to the table. Continuous process improvement efforts were very evident throughout his facility in multiple departments and he was setting standards for other’s to emulate. Much of his success was his ability to bring cross functional teams together, identify roles, responsibilities and set clear goals.

Geoffrey is a customer focused operations manager. He is skilled at logistic planning and inventory management.

Geoff Koboldt is one of the most energetic people I have ever had the pleasure of working with. He has great ideas and is dedicated to his work. His desire to seek improvement in anything he does is inspirational and made me strive to be better in anything I do.

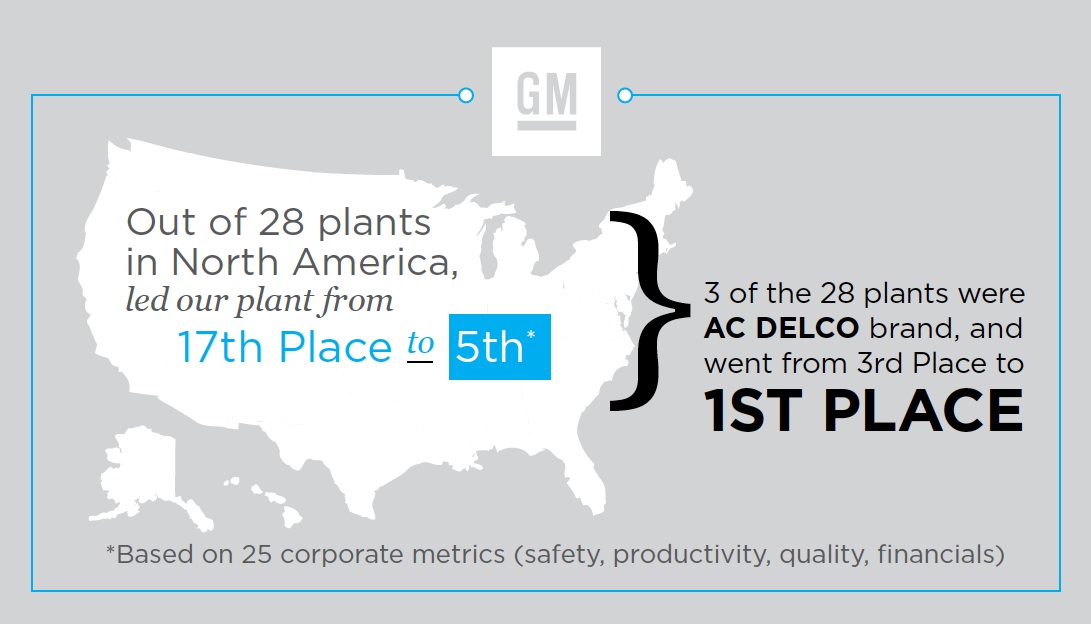

General Motors Corp., AC Delco, Fontana, CA – Inventory Control Manager 1/2004 – 4/2005; Outbound Operations Manager & Quality Network Manager 6/2001 – 12/2003; Inbound Operations Manager 5/2000 – 5/2001 Managed 52 UAW and 8 salaried employees during tenure for this $250M after-market product division. Results: saved $10M+ championing over 20 lean six sigma projects earning Lean Silver certification

- Championed lean six sigma projects: area optimization, cycle throughput, slotting inventory, takt time, 5S, etc.

- Led quality improvements by 34% instituting a new process for quality assurance while ensuring productivity increases.

- Increased productivity 50% in outbound department from 28 lines per hour to 42 lines per hour and 15% for inbound.

- Earned #1 AC Delco plant and raised performance ranking to #5 out of 28 plants from 17th place, based on 25 metrics.

- Increased cycle count accuracy to over 99.5%, managing over 500+ skus.

- Reduced stockouts by 10%.

Geoff is an extremely talented leader who drove continuous improvement in all areas of the business through innovation, creativity, planning and execution. He was able to resolve complex problems and implement solutions through collaboration and superior leadership. Geoff was highly regarded by the workforce as well as upper management. His presentation skills are unmatched. I was extremely fortunate to have Geoff on my Leadership Team at the GM/SPO ACDelco Warehouse in Fontana, CA.

I enjoyed working with Geoff. He is strategic and knows how to connect with all levels within an organization. He is very efficient and proactive in reaching his goals and he thinks outside the box when problem solving. Geoff, led many quality improvements and Kaizen projects with successful results.

Geoff was a pleasure to work with. I was amazed at his ingenuity at handling complex situations with the Union. He came up with win win solutions and earned the respect of both parties in several situations. I whole-heartedly recommend Geoff.

I met Geoff at the beginning of my career at General Motors. During that time I was able to capture a glimpse of what Geoff’s capabilities were and over the last 9 years I have witnessed his evolution and advancement in business. Geoff embodies and is a true “think outside of the box” professional. He is creative, resourceful, and resilient. It has been a pleasure to know him for all of these years as I hold a great deal of respect for him as a person, and as a professional.